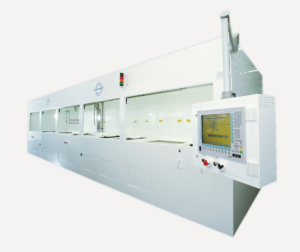

Semiconductor Equipment – Plating

Since 1972, company RAMGRABER is successfully working in the production of plating systems for the electronics industry. Over the course of the ensuing decades, we have been continually expanding our knowledge in the field of galvanic processes.

You can also benefit from the advantage we offer your – our extensive experience in electroplating of semiconductors, electronics components, solar cells and microsystems.

Thanks to close cooperation with leading research institutes and our customers, we are able to offer you solution-oriented support when optimizing your processes.

Plating: Overview

Possible Options

Substrate Types: Si, III-V-semiconductor, ceramic, metal, glass

round or square

Plating Materials: Ag, Au, Cu, Pd, Ni, Sn, AuSn, PbSn, NiCo etc.

Plater Types: Rack, Fountain

Substrate Arrangement: vertical, horizontal, oblique

Substrate Holder: single holder, multiple holder, sealing of the backside, sealing around the contact areas

Electrical Contact: front- or backside, isolated or free

Electrolyte Flow towards Substrate: through the line of force shield, flow parts in motion

Movement: horizontal, vertical, Rotation, oscillation

Electrolyte Preparation: heating and cooling, filtration, dosing systems, selective cleaning

Tank Material: PP – welded or deep drawn, PVDF – welded or deep drawn, PE, PVC, high-grade steel – with anodic protection

Protective Gas Atmosphere: for fast oxidizing electrolytes

Heating and Cooling: direct or indirect heating, PTFE or PFA coated, quartz heater, radiation heater, large area heater to avoid overheating

Measuring: current / voltage, temperature, filling level, flow rate, resistivity, pH-value, concentration via absorption or titration

Power Supply: high exactness, minor ripple, pulse plating

Automation Level: manual, semi-automatic, fully automatic

Quality of Process Area: up to class 10, integrated laminar flow box, optimized air flow in the process area

Handling Systeme: Two-axis handler, roboter

In-Output-Carrier: standard oder special carrier, single substrate

Control System: switchgear, SPS, Industry PC, Touch Screen, visualisation systems

Identification System: Transponder, Barcode

Software: solutions on customer requirements

Pre- and After-Treatment Processes: rinse, clean, etch, dry, reflow

Ramgraber systems convince through:

- Homogeneous plating

- Reproducibility

- Ideal shield technique

- Cost effective Design

- High-quality components

- High throughput rates

- longevity

- High maintainability

- Our competent service