Precleaning + Deglueing

DEGLUE STAR® This fully automatic production system (3-shift-operation) serves the precleaning and deglueing of sawn Si-ingots.

The mode of operation: First all Si-Ingots are precleaned, then the carrier material is removed through a chemical/thermal process. This chemical/thermal process removes the glue between the Si-ingot and the carrier material.

You can also profit from our great experience in building Precleaning + Deglueing Systems. We will be delighted to be there for you !

Saw damage etching / Polish etching

BATCHSTAR® Fully automatic Batch Systems made by RAMGRABER convince through stable processes with the required reproducibility as well as through a very high uptime. In this equipment-example the system serves for acidic as well as alkaline saw damage etching.

A modular configuration is part of our sophisticated design. Despite the minimal footprint, all components are arranged in such a way that RAMGRABER Batch Systems are very easy to operate and maintain.

You can also profit from our great experience in building Batch Systems. We will be delighted to consult you!

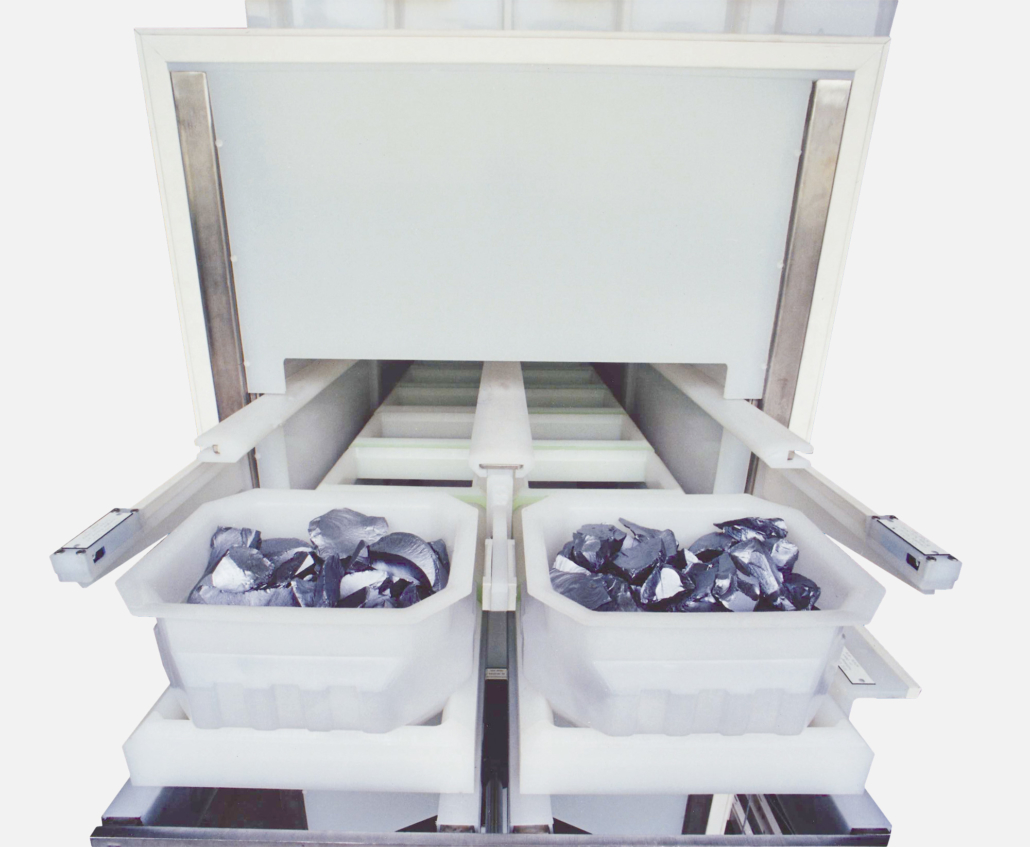

Poly-silicon chunks

CHUNKSTAR®

The fully automatic etching system (3-shiftoperation) serves to remove organic and metallic contaminations from the surface of the poly-silicon chunks.

The chunks are transported through the wet chemical cleaning process in special goods baskets. During the process, they run through various etching and rinsing steps. Afterwards the chunks are dried.